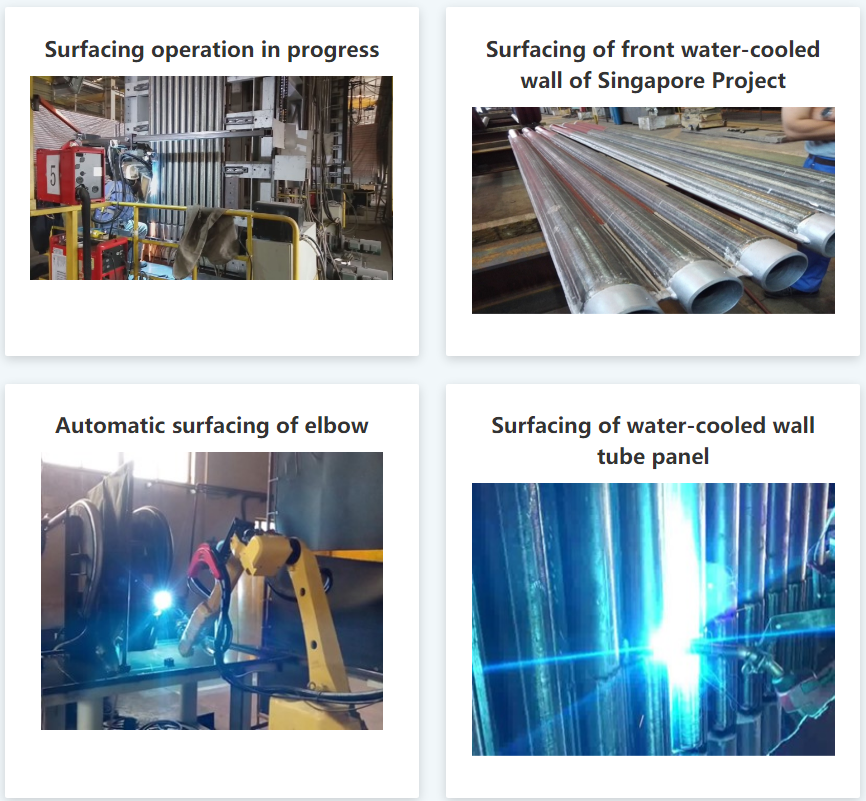

CMT welding machine is adopted for EBARA Environmental Engineering (China) Co., Ltd. surfacing, and its main features are as follows:

Cold metal transition:

CMT welding machine adopts cold metal transfer principle to surfacing, and the heat produced by CMT welding machine is only half of that of common surfacing machine, which can effectively slow down the failure rate of 625 alloy.

Wide range of surfacing:

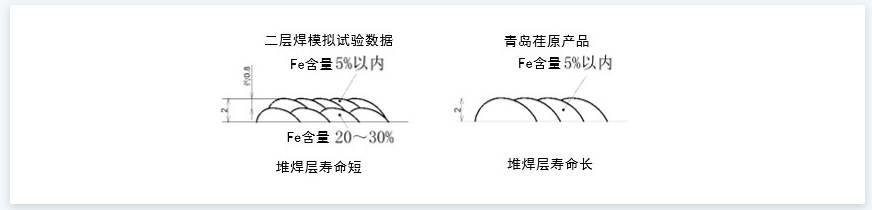

CMT welding machine can achieve three kinds of thicknesses, 1.6mm, 2.0mm and 2.5mm by only one layer of overlaying welding, and the Fe dilution rate can be controlled within 5%.

Good surfacing quality:

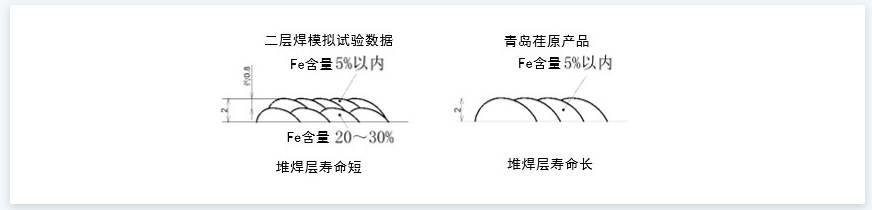

Ordinary welding machine (pulse MIG) can control the dilution rate of Fe on the surface layer within 5% with two layers of surfacing. As the dilution rate of the two layers is discontinuous, once the corrosion breaks through the surface layer, the corrosion rate of the inner layer will increase exponentially, thus affecting the service life of the whole surfacing layer; while the CMT surfacing process adopted by our company is far more advanced than the ordinary surfacing process, and the dilution rate of Fe can be controlled within 5% only by one layer, and the dilution rate from the surfacing layer to the base metal is continuous, the corrosion rate is constant, and the service life of the surfacing layer is effectively guaranteed.

Slow thinning rate:

According to the inspection data of the surfacing surface of Japanese customers, CMT surfacing process is adopted, which is mature and reliable, and the thinning rate is very low. The thinning is about 0.05mm/year.

Unique CMT single-layer surfacing process, the service life reaches the industrial flat top level

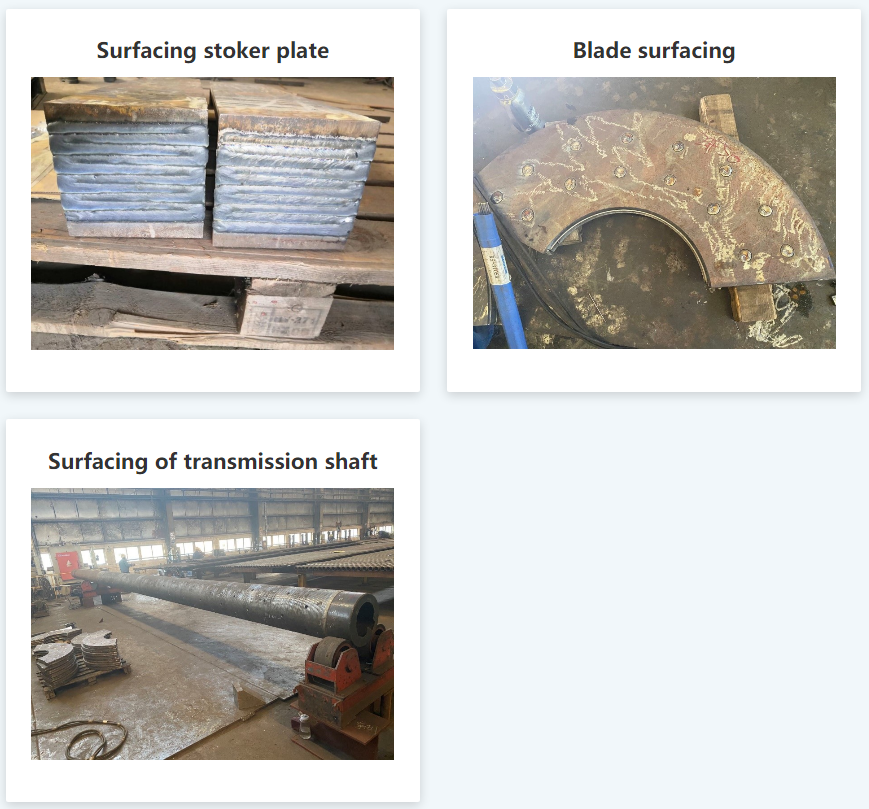

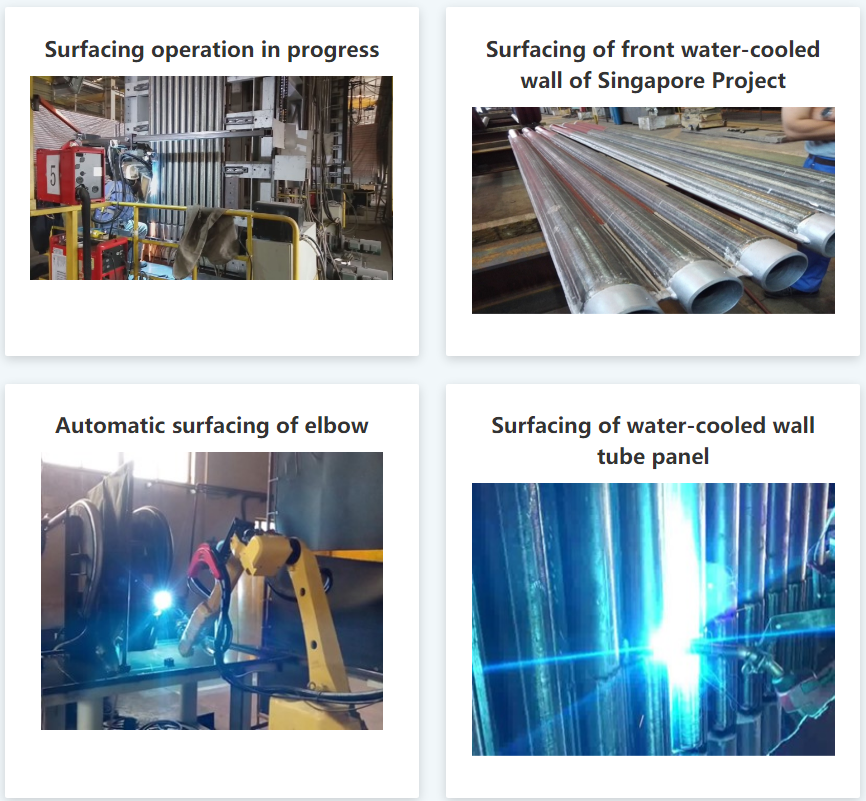

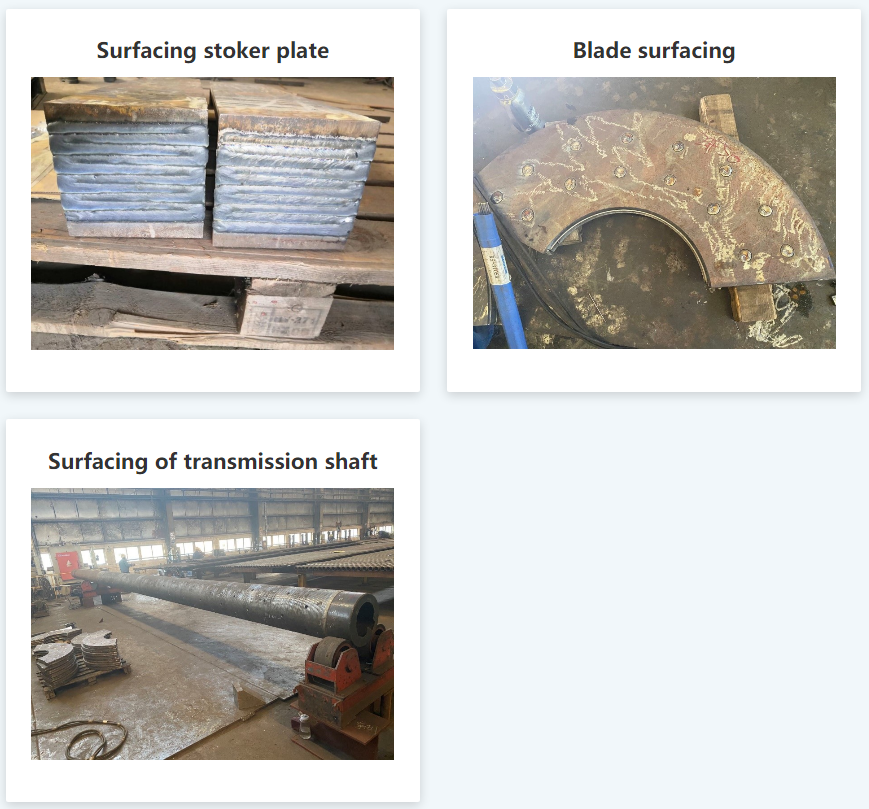

Surfacing Capacity Description

EBARA Environmental Engineering (China) Co., Ltd. has more than 200 sets of various welding equipment and professional tooling, including more than 20 kinds of welding machines, tooling and robots for surfacing. See the following list for details, and the surfacing capacity of our company is about 1200m2/month.

| No | Equipment name | Equipment number | Remarks |

| 1 | Forness CMT welding machine | 18 |

|

| 2 | Vertical surfacing device | 8 | For tube panel |

| 3 | Horizontal rotary surfacing device | 3 | For tube panel |

| 4 | Site area | 3300 square meters | 4 |

| 5 | Number of operating personnel | 32 persons |

|

Surfacing items

| No. | Project name | Country | Signing time of the contract | Surfacing area (m2) |

| 1 | Kitakyushu Project | Japan | February 2012 | 173 |

| 2 | Musashino Cleaning Center Project | Japan | May 2014 | 35 |

| 3 | Cleaning Center Project in Funabashi | Japan | June 2014 | 206 |

| 4 | Cleaning Center Project in Funabashi | Japan | March 2015 | 75 |

| 5 | SINCERE RC Center Project | Japan | April 2015 | 199 |

| 6 | ECO Planned Construction Project | Japan | October 2015 | 17 |

| 7 | Minami Shinshu Joint Agency Project | Japan | October 2015 | 13 |

| 8 | Singapore No. 6 Garbage Incineration Power Plant Project | Singapore | October 2015 | 3888 |

| 9 | Kuwana Wide Area Cleaning Business Combination Project | Japan | August 2017 | 114 |

| 10 | Saku-Kitasaku Environmental Facilities Portfolio Project | Japan | December 2017 | 36 |

| 11 | Higashihari Coastal Wide Area Project | Japan | February 2018 | 181 |

| 12 | Aomori Project | Japan | April 2018 | 243 |

| 13 | Minoh Environmental Cleaning Center Project | Japan | October 2018 | 53 |

| 14 | ECO Planned Construction Project | Japan | November 2018 | 12 |

| 15 | Fujisawa North Project | Japan | April 2019 | 87 |

| 16 | Sanboku Biomass Plant Construction Project | Japan | September 2019 | 627 |

| 17 | Surfacing Project of Hiroshima Central Factory Project | Japan | September 2019 | 719 |

| 18 | Sano 2 boiler project | Japan | September 2019 | 11 |

| 19 | Japan Iron & Steel OG Lower cover project in Kimitsu | Japan | December 2019 | 106 |

| 20 | Izu Project | Japan | June 2020 | 41 |

| 21 | Sano No. 1 and No. 3 boiler project | Japan | July 2020 | 22 |

| 22 | Tachikawa Project | Japan | September 2020 | 17 |

| 23 | Sakai City Project | Japan | October 2020 | 41 |

| 24 | Hamamatsu Boiler Project | Japan | April 2021 | 655 |

| 25 | Kosei Project | Japan | July 2021 | 84 |

| 26 | Sakai City Project | Japan | September 2021 | 89 |

| 27 | Waste Heat Boiler Equipment Procurement Project of Chongming Solid Waste Disposal and Comprehensive Utilization Center Phase II Project | China | May 2019 | 440 |

| 28 | Waste Heat Boiler Surfacing Water Wall Supply Project for Urban Waste Centralized Disposal Project in Ying (Shan)-Peng (An)-Yilong (Long) of Nanchong City | China | November 2019 | 1205 |

| 29 | Waste Heat Boiler Surfacing Project in Xinchang County | China | May 2020 | 470 |

| 30 | Shanghai Fengxian Waste Heat Boiler Surfacing Project | China | June 2020 | 1062 |

| 31 | Boiler Surfacing Water Wall Parts Strip Material Processing and Outsourcing Manufacturing and Supply Project for B&WBC Zhangjiagang Domestic Garbage Incineration Project | China | January 2021 | 632 |

| 32 | Waste Heat Boiler Surfacing Water Wall Supply Project for Hechuan Domestic Garbage Incineration Power Generation Project | China | February 2021 | 546 |

| 33 | Shangguo Baoshan Project | China | June 2021 | 2422 |

| 34 | Taiwan Taoyuan Project | China | October 2022 | 756 |

|

|

|

|

|

EN

EN

EN

EN

Online consultation

Online consultation

2025-02-17

2025-02-17