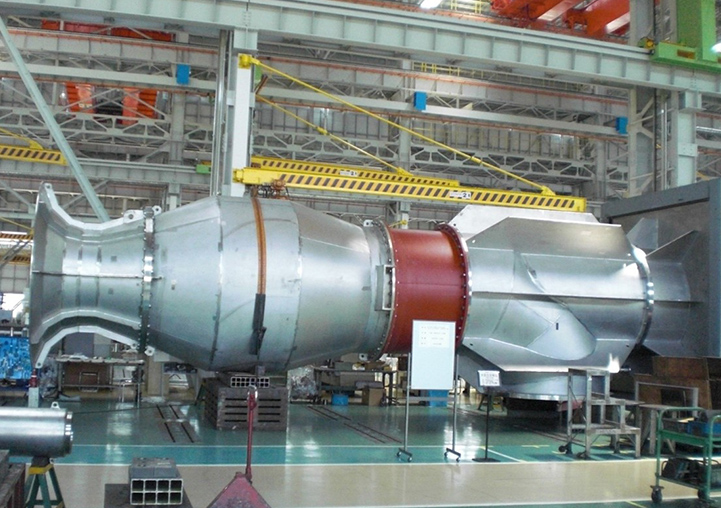

Ebara Environmental Engineering adopts the patented HPCC21 grate for the incineration treatment of household waste.

Denitration – SNCR, SCR

SNCR, the full name is selective non-catalytic reduction in English, refers to the reduction of nitrogen oxides in flue gas into harmless nitrogen and water by injecting reducing agent (ammonia or urea) into the “temperature window” suitable for denitration reaction without the effect of catalyst. Selective catalytic reduction (SCR) technology is a process for treating NOx in the exhaust gas of diesel vehicles, i. e. the reducing agent (ammonia or urea) is injected under the action of catalyst, so as to reduce the NOx in the exhaust gas to N2 and H2O.

Deacidification – CFB Dry, Semi-dry, Wet

The raw flue gas and the absorbent enter the reactor through the regulating rotor, and the reaction product is carried by the flue gas and separated by the dust remover, and is humidified by the return system and then returns to the return device. The humidified dust, absorbent and reaction products form a high-concentration rapid bed in the reactor, and the surface of the absorbent is continuously renewed here, so that the deacidification reaction is continuously promoted.

SDA Semi-dry Deacidification Process

Guided by the air inlet flue, the raw flue gas enters the reaction tower from the top rotating downwards, the lime slurry is dragged and sheared into tiny particles through an atomizing disc, heat transfer and mass transfer are carried out in a liquid film on the surface of the particles, and acid substances such as HCI and SO2 in the removed flue gas are discharged after being filtered by a bag-type dust collector.

Wet Washing Process-sodium-alkali Method

Integrated tower technology of single-tower double-circulation is adopted, and high-temperature flue gas enters from the lower part and is discharged after passing through a cooling absorption part and a dehumidification absorption part. Acidic pollutants, superfine dust and aerosol are removed, and gaseous water in the saturated flue gas is condensed and separated out.

EN

EN

EN

EN

Online consultation

Online consultation

2024-09-13

2024-09-13